The account number and password do not match, please re-enter

-

Please enter account name

-

Please enter your password

Login with verification code Forgot your password

The account number and password do not match, please re-enter

-

Please enter your mobile phone number

-

Get verification code

Please enter SMS verification code

Login with Password

The account number and password do not match, please re-enter

-

Please enter your email address

-

Get verification code

Please enter email verification code

Login with Password

Forgot your password

Blast pipe dry steam humidifier

Blast pipe dry steam humidifier

Category:

Detail

1.Working principle and schematic diagram:

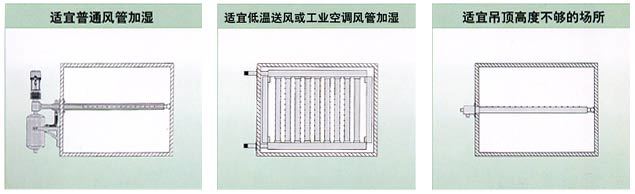

It installs dry steam humidifier in the humidifying blast pipe. Generally, if the combined air conditioner or fresh fan unit has no sufficient humidifying space for installing dry steam humidifier (For example, ceiling type fresh fan unit coil and fan cling together), putting dry steam humidifier forcedly will cause that the sprayed vapor will be blew into fan without sufficient dispersion and the vapor condenses with water. As a result, wind tunnel and air conditioner deposit water. Evenly, the fan motor will be broken. Thanks to wet-film dash plate and no blockage in the wind tunnel, blast pipe dry steam humidifier has sufficient vapor dispersion space. So it has no troubles said above.

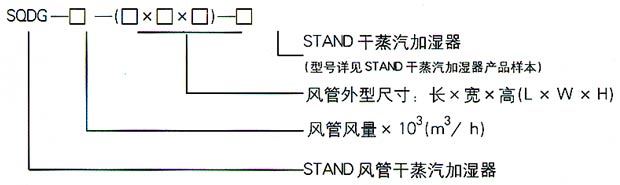

2.Model description:

3.Technical parameter table of blast pipe dry steam humidifier:

|

Model |

SQDG |

|||||||||||||||

|

-1 |

-2 |

-3 |

-4 |

-5 |

-6 |

-7 |

-8 |

-9 |

-10 |

-12 |

-15 |

-18 |

-20 |

-25 |

-30 |

|

|

Max ventilation(m3/h) |

1000 |

4000 |

3000 |

4000 |

5000 |

6000 |

7000 |

8000 |

9000 |

10000 |

12000 |

15000 |

18000 |

20000 |

25000 |

30000 |

|

Pressure loss |

<30Pa |

|||||||||||||||

|

Note: Humidifying capacity of blast pipe dry steam humidifier is up to the user. View details about model selection in sample product of STAND2001ed dry steam humidifier. |

||||||||||||||||

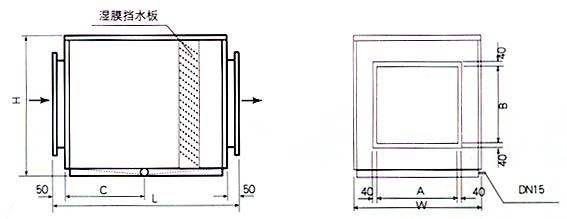

4.Overall size drawing of blast pipe:

|

Model |

SQDG |

|||||||||||||||

|

-1 |

-2 |

-3 |

-4 |

-5 |

-6 |

-7 |

-8 |

-9 |

-10 |

-12 |

-15 |

-18 |

-20 |

-25 |

-30 |

|

|

A |

620 |

970 |

1220 |

1520 |

1720 |

1620 |

1820 |

2020 |

2520 |

3020 |

||||||

|

B |

420 |

420 |

520 |

520 |

620 |

820 |

||||||||||

|

C |

350 |

|||||||||||||||

|

L |

800 |

|||||||||||||||

|

W |

700 |

1000 |

1300 |

1600 |

1800 |

1700 |

1900 |

2100 |

2600 |

3100 |

||||||

|

H |

500 |

500 |

600 |

700 |

900 |

|||||||||||

|

Example 1—Model selection of blast pipe single layer pipe dry steam humidifier Suppose: Blast pipe ventilation of some project is 2,000m3/h, humidifying capacity is 16kg/h, steam line pressure is 0.2mpa, ceiling height is 600mm, and ceiling type fresh fan unit has no humidifying section. The client wants to select electric two-way valve dry steam humidifier.

Suppose: Blast pipe ventilation is 2,000m3/h, and ceiling height is 600mm. we design to select blast pipe with 500mm height and 700mm width (generally, the wind speed in the humidifying blast pipe is less than 3m/s).

And suppose: Humidifying capacity is 16kg/h, and steam pressure is 0.2mpa. Viewing sample products of STAND dry steam humidifier, SQE(D)-15-Φ6-M2 can be chosen.

And because if the blast pipe is 700mm wide, the first choice for spraying pipe of dry steam humidifier is L3.

→So the user should select the following model:

SQDG-2-(800×700×500)-(SQE(D)-15-Φ6-L3-M2)

Note: Humidifying blast pipe size: L×W×H=800×700×500。 |

|

Example 2—Model selection of blast pipe quick-absorption vaporization humidifier Suppose: Blast pipe ventilation of some project (industrial workshop) is 15,000m3/h, humidifying capacity is 130kg/h, steam line pressure is 0.2mpa, and no ceiling. The client requests to use low-temperature air supplying mode (because of large heating effect of workshop), with air supply relative humidity up to over 90%. There is no suitable humidifying section in air conditioning unit. The client wants to select electric regulating valve dry steam humidifier.

Suppose: Blast pipe ventilation is 15,000m3/h, and no ceiling height limit. Considering even airflow mixing, we design to select blast pipe with 900mm height, 1,700mm width (generally, the wind speed in the humidifying blast pipe is less than 3m/s), and 800mm length.

And suppose: Humidifying capacity is 130kg/h, and steam pressure is 0.2mpa. So it is low-temperature high-temperature air supplying industrial project. Vapor quick-dispersion type humidifier is recommended, so as to prevent side condensation trouble of wind tunnel caused by untimely vapor dispersion. Viewing sample products of STAND quick-absorption type vaporization humidifier, SQK-900*1,700-7 can be chosen.

So the user should select the following model:

SQDG-15-(800×1700×900)-(SQK-900×1700-7)

Note: Humidifying blast pipe size: L×W×H=800×1700×900 |